Frequently Asked Questions

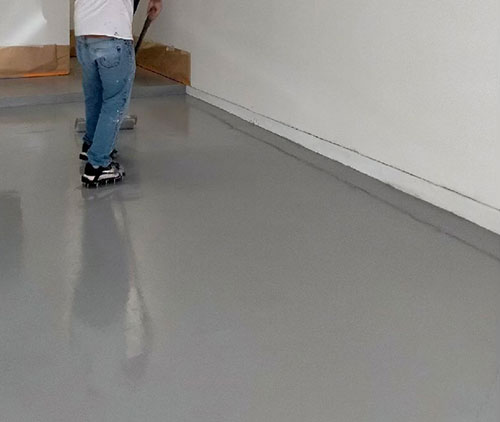

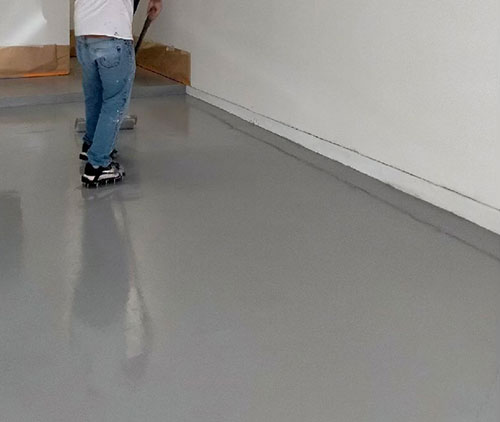

What to know and expect before you book a concrete floor coating project.

Is this really a 1-day project?

Yes! In most cases we complete your entire residential garage floor — from prep to top coat — between 8 am and 6 pm on your scheduled work day. You can walk on the floor in a few hours, and drive on it the next day.

While traditional epoxy floor coatings can take your garage out of commission for several days, our technologically advanced coatings cure much faster.

What is a moisture test, and why do I need one?

If your concrete reads more than 5.5% moisture content, it’s critical to apply a moisture barrier before coating.

Fortunately very few projects in your area require a moisture barrier. If required, a moisture barrier increases cost and adds an extra day to the project.

My floor has cracks — will they show through the coating?

Our surface preparation process begins with grinding, filling and sealing any significant cracks in your floor.

The color chips in our standard 3-layer coating system do a fantastic job of hiding imperfections, so you’ll never know they were there.

What about expansion or contraction joints?

When we meet for your initial consultation or moisture test, we’ll have a look and help you decide on the best solution.

My garage has a tire stop or a step-up. Will that be coated?

Yep, this is part of your concrete slab, and we’ll coat the vertical surface to match the rest of your floor.

Should I coat my concrete stairs and cove base?

We can coat almost anything made of concrete, thanks to our superior quick-curing products. However, we sometimes recommend going with a high-quality masonry paint for your concrete stairs and cove base to achieve a more uniform look.

How does the initial consultation work?

We’ll estimate your project space, assess the condition of your concrete, and help you determine the best solution for your needs.

Do I need to be home on installation day?

No, just arrange for us to have access to your garage or project space, and you’ll come home to a brand new coated floor at the end of the day. Please be sure everything has been cleared off the floor when we arrive.

What do I need to do to prepare for installation day?

Do I need to clear out my garage or project space?

How can I store my stuff during the project?

Will you be using my electricity for the project?

Our industrial diamond grinders and HEPA-filtered air scrubbers would overload a standard household circuit. That’s why we bring our own 15 kilowatt generators, which supply all the power we need. They’re noisy like a lawnmower, but we’ll do our best to direct it away from your living space if you’re home.

How do I clean my new floor?

You’ll be amazed at how much cleaner your garage stays with our floor coating system. For general tidying, you’ll find a leaf blower is far more effective at removing dust and dirt than it was with your old concrete floor.

For periodic cleaning, warm vinegar water and a mop is all you need.

Do NOT pressure wash your new floor because this can damage the topcoat!

Do I need to worry about damaging my new floor?

Once the top-coat is fully cured, your floor is impervious to most chemicals, oils, etc. The one exception is strong acids (e.g. battery acid), which will eventually eat through almost anything, including a chemical floor coating.

In the event you have a battery leak, please be sure to clean it up with water and vinegar right away.

As with any flooring surface, avoid sliding anything sharp and heavy across your floor, as this can scratch the surface.

Is a coated floor slippery to walk on?

Not under normal, dry conditions. However, any surface can become slippery when wet due to hydroplaning or ice accumulation.

The chip layer in our standard 3-layer coating system adds texture to your floor to discourage hydroplaning, and we include an anti-slip grit to your topcoat to help keep your feet on the ground where they belong.

Is this really a 1-day project?

Yes! In most cases we complete your entire residential garage floor — from prep to top coat — between 8 am and 6 pm on your scheduled work day. You can walk on the floor in a few hours, and drive on it the next day.

While traditional epoxy floor coatings can take your garage out of commission for several days, our technologically advanced coatings cure much faster.

What is a moisture test, and why do I need one?

If your concrete reads more than 5.5% moisture content, it’s critical to apply a moisture barrier before coating.

Fortunately very few projects in your area require a moisture barrier. If required, a moisture barrier increases cost and adds an extra day to the project.

My floor has cracks — will they show through the coating?

Our surface preparation process begins with grinding, filling and sealing any significant cracks in your floor.

The color chips in our standard 3-layer coating system do a fantastic job of hiding imperfections, so you’ll never know they were there.

What about expansion or contraction joints?

When we meet for your initial consultation or moisture test, we’ll have a look and help you decide on the best solution.

Should I coat my concrete stairs and cove base?

We can coat almost anything made of concrete, thanks to our superior quick-curing products. However, we usually recommend going with a high-quality masonry paint for your concrete stairs and cove base for a few reasons:

- It usually looks better, especially on cove base. Most cove base tends to be pretty rough, even after we hit it with a hand grinder. With masonry paint, we can achieve a more uniform look.

- It costs less. In fact, we’ll paint the concrete stairs and cove base in most residential floor coating projects at no additional charge.

- It performs great. You won’t be driving on your stairs and cove base. A quality masonry paint will last for years, and you can easily change the color in the future if you change the color of your walls.

My garage has a tire stop or a step-up. Will that be coated?

Yep, this is part of your concrete slab, and we’ll coat the vertical surface to match the rest of your floor.

How does the initial consultation work?

We’ll estimate your project space, assess the condition of your concrete, and help you determine the best solution for your needs.

Do I need to be home on installation day?

No, just arrange for us to have access to your garage or project space, and you’ll come home to a brand new coated floor at the end of the day. Please be sure everything has been cleared off the floor when we arrive.

What do I need to do to prepare for installation day?

Do I need to clear out my garage or project space?

How can I store my stuff during the project?

Will you be using my electricity for the project?

Our industrial diamond grinders and HEPA-filtered air scrubbers would overload a standard household circuit. That’s why we bring our own 15 kilowatt generators, which supply all the power we need. They’re noisy like a lawnmower, but we’ll do our best to direct it away from your living space if you’re home.

How do I clean my new floor?

You’ll be amazed at how much cleaner your garage stays with our floor coating system. For general tidying, you’ll find a leaf blower is far more effective at removing dust and dirt than it was with your old concrete floor.

For periodic cleaning, warm vinegar water and a mop is all you need.

Do NOT pressure wash your new floor because this can damage the topcoat!

Do I need to worry about damaging my new floor?

Once the top-coat is fully cured, your floor is impervious to most chemicals, oils, etc. The one exception is strong acids (e.g. battery acid), which will eventually eat through almost anything, including a chemical floor coating.

In the event you have a battery leak, please be sure to clean it up with water and vinegar right away.

As with any flooring surface, avoid sliding anything sharp and heavy across your floor, as this can scratch the surface.

Is a coated floor slippery to walk on?

Not under normal, dry conditions. However, any surface can become slippery when wet due to hydroplaning or ice accumulation.

The chip layer in our standard 3-layer coating system adds texture to your floor to discourage hydroplaning, and we include an anti-slip grit to your topcoat to help keep your feet on the ground where they belong.

More questions? That’s what we’re here for. Click here for our contact info.

How Much Does Concrete Floor Coating Cost?

Answer a few simple questions about your project for a free, instant estimate.

- No email required

- No Phone Required

- Proposals By Request